.

Software Consulting/ Software Training

|

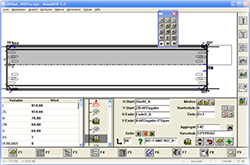

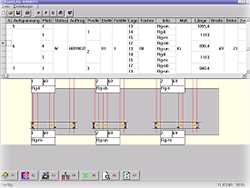

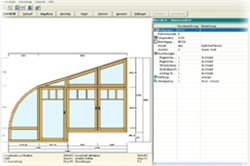

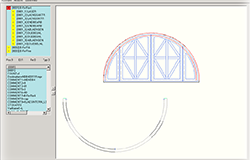

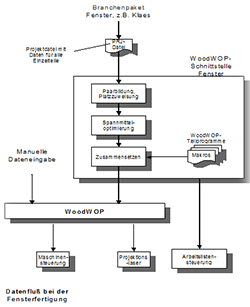

A CNC machining center can be controlled with several different software programs. There are huge differences in the possiblilities, performance, quality and price. Software comes in many different levels. Current software for CNC machines can be installed on ordinary PC's running all the major operating systems. The lowest level of programming on a CNC machining center is the so-called DIN / ISO programming. This refers to the standard DIN 66025/ISO 6983. Within individual statements so-called G commands are used, which are combined with addresses and numbers. The DIN code consists entirely of numeric program lines, which can be created and edited using a simple text editor. In general, G code can be processed by any CNC machine through the standard structure, although there are different dialects. Programming and testing is difficult because of the lack of a graphical user interface. Errors can be easily overlooked because of this. However, programs are ultimately reduced by each parent program through translation (the so-called generation) to DIN code. For this reason, the DIN / ISO programming can be useful for the machine operator if he uses this knowledge to repair programs. Shop floor programming, also called SFP, is the next level in the software technical control of a CNC machining center. Known applications of the timber industry are Woodwop (Homag, Weeke) IMAWOP and other similar applications. Individual processing steps on a part, such as drilling, milling or sawing can be programmed. The Windows-based, dialogue-driven interface is very user-friendly, simple and easy to learn. The part is displayed with the individual processing steps using a graphical user interface. The graphic area is immediately visible, which was numerically programmed. This principle is also called: "What you see is what you get". Everything that has been programmed can immediately be checked simply by consulting the graphic display. This makes it much easier to discover errors in comparison to DIN / ISO programming, where one only sees rows with numeric values. The individual CNC machining steps, called macros, are listed consecutively and can be comfortably changed, moved and deleted. Only the queries within the processing type specific macros are run which are immediately necessary for this processing step. Additional entries for other parameters are possible. Even the vacuum and clamps are programmed in SFP(WOP). The SFP(WOP) program is translated through CNC generation to DIN / ISO code which drives the machine. CAD / CAM software works project-oriented and is much more complex. CAD / CAM software is programmed to be product-related in general. In addition to the automatic creation of CNC programs for a complete product or project, it fulfills a variety of other production and operational tasks in the production process because it is mostly designed to be industrial software. In any case it usually operates with settings, which are taken from a database. Master data dependent construction guidelines and component techniques are established with which the desired products can be constructed. The company must therefore develop its own construction methods and form standards. A professional CAM module creates a, more or less, machine-independent DIN / ISO program directly from within the software, with access to its own tool database. Any changes or modifications to this program on the part of the operator are no longer necessary. The more powerful this CAM module is, the more optimized the CNC machining is regarding the expiry, quality and feed rate. Nevertheless, these programs are limited. In any case, a CAD / CAM software must be individualized with respect to the master data structure and construction methods determined by the company. This expense is relatively high, costly, and should be carefully planned. However, if the adjustment is carried out as extensively as possible, such software is much more powerful and faster than that of other systems. Siebert Engineering helps you in choosing and setting up this software. Software suppliers quite often offer training courses. Siebert engineering also offers courses and individual on-site training and instruction. Take advantage of all the expertise of Siebert Engineering and get a free quotation for our services.

|

|

How to find us.

Schauenburg near

Kassel conveniently

access by

car, train

Aircraft

More information