.

Window Tools Technology

|

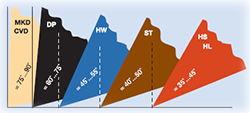

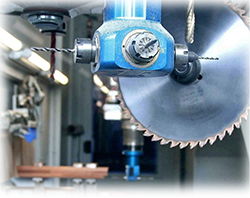

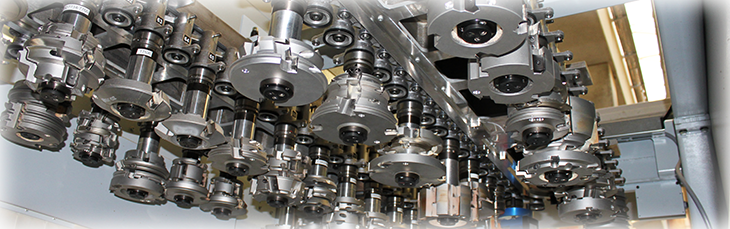

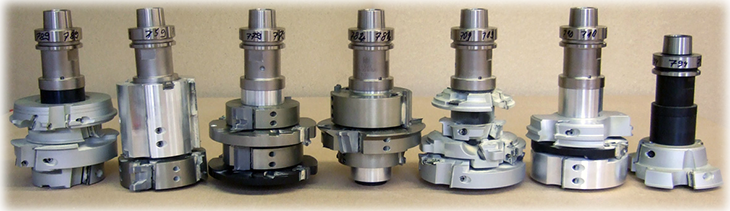

Advise on the selection of appropriate tools and the reduction of tool costs, especially when it comes to the details of CNC machining, is extremely important because the switch to new tools is directly associated with the corresponding window systems technology and the existing or new concept for machine investment. The bevel geometry is produced in two or more passes with a tool set with profile splitting. The tools are designed so that, for example, one half of the bevel configuration is milled in the first step and then the other half in the second step. This requires, for example, an window production centre with at least two NC-controlled spindles for longitudinal profiling and also possibly two spindles for the transverse profile. In a traditionel window production centre it has multiple stroke and the tools are distributed on both spindles so that the entire bevel configuration can be generated in a single pass. In a CNC machining center with a main spindle, it is useful to have the complete profile split on a carrier. First the outer profile will be approached and then by z-dimension offset the inner profile. The machine does not need to change the tool with this solution, since both profiles are on a carrier. You only move back and forth twice. There are now machining centers with multiple independently operating processing heads. Tool splitting can potentiate the number of profiles while reducing the number of tools. This, however, must be carefully planned, because efficiency and capacity decreases. Get independent advice from Siebert engineering in addition to the advice from the trusted expert advisor of your tool manufacturer. You will soon discover how much cost you can save and how to avoid errors in the details.

|

|

How to find us.

Schauenburg near

Kassel conveniently

access by

car, train

Aircraft

More information